For a company like Polimerbio, whose goal is to become a manufacturer of medical devices, developing a quality management system is a fundamental step.

It is possible to develop products that are highly innovative or technically superior to the competition, but if a company is not able to ensure that it works under proven safety and efficacy conditions, it will not be able to market its products.

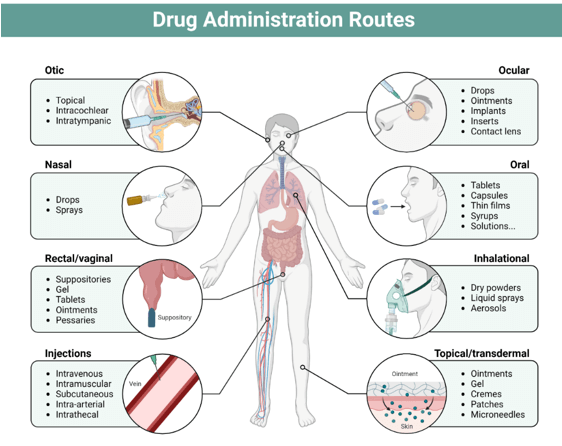

“The regulations and directives that apply to us are very demanding and no wonder, since we are talking about products that directly affect people’s health,” explains David Geijo, Industrial Engineer and Head Regulatory at Polimerbio. As he notes, taking into account the special characteristics of Polimerbio’s first product, it is classified as a class III medical device, meaning that it has a higher inherent risk for the patient.

“Therefore, we are required to go through a much deeper and more thorough design, development, production and market monitoring process than for lower-rated products. To give people an idea, in our case it is mandatory to conduct clinical trials with patients, something that is not usually necessary for most products if you have good animal testing and extensive scientific literature to support the design and development stages,” he says.

Quality being a fundamental aspect in Polimerbio’s activity, the company is currently finishing the development of some processes required by the ISO 13485:2016 standard, a process that is expected to be completed before the end of the year. From that point on, Polimerbio will focus on the implementation of the processes in place since September- and which will continue throughout the first quarter of 2022.

According to David Geijo, once the quality system is in place, the team will be trained in some key aspects such as risk management, clinical evaluation and post-marketing follow-up of medical devices, among others.